Life Cycle Cost Estimating

Overview

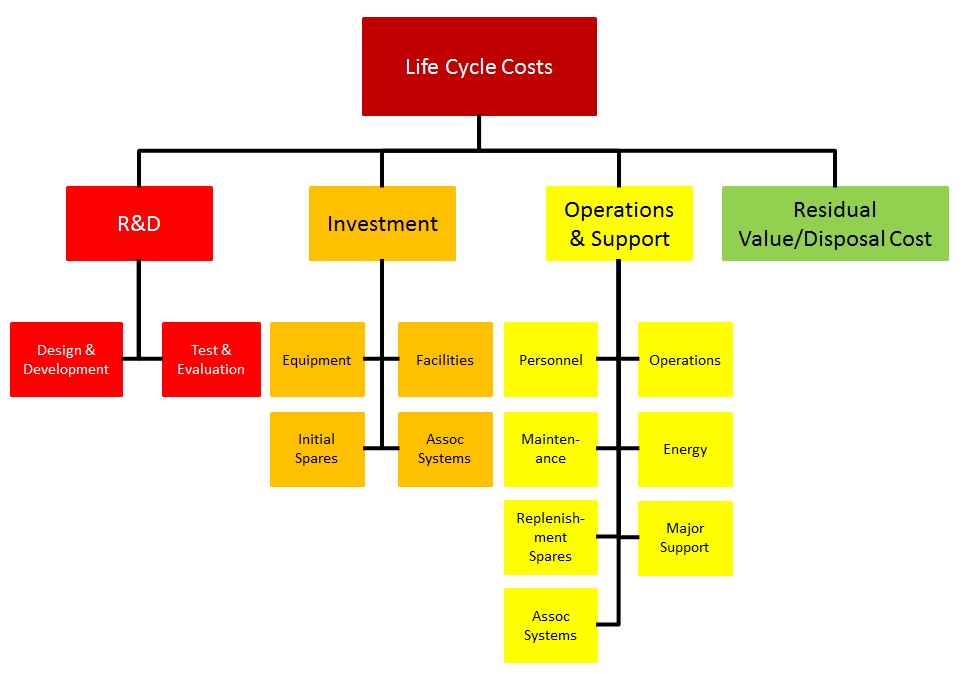

Although there are numerous required inputs to the Life Cycle Costs calculations, many of them can be left as their default values, and overall the actual calculations are relatively stright forward. The figure below shows the overall general overview of what is included in the Life Cycle Cost Calculations.

Required Inputs

The method used for estimating the Life Cycle Costs in the spreadsheet requires the following inputs;- Total Crew

- Ship Service Life

- Production Rate

- Total Number of Ships in Class

- Year 1st of Class in Service

- Learning Rate Factor

- Research & Development Cost Factors

- Ship Design & Development Factor

- Basic Ship Construction Design & Development Factor

- Government Military Payload Design & Development Factor

- Ship Test & Evaluation Cost Factors

- Ship Test & Evaluation Factor

- Basic Ship Construction Test & Evaluation Factor

- Government Military Payload Test & Evaluation Factor

- Payload Hardware Test & Evaluation Factor

- Shore Based Support & Repair Parts Factors

- Ship Support Equipment Factor

- Payload Support Equipment Factor

- Ship Spares & Repair Parts Factor

- Payload Spares & Repair Parts Factor

- Personnel (Pay & Allowance) Cost Factors

- Officer Cost Factor

- CPO & Enlisted Cost Factor

- Temporary Assigned Duty (TAD) Factor

- Operations Cost Factors

- Operations Cost Factor 1

- Operations Cost Factor 2

- Operating Hours Cost Factor

- Average Ship Cost Factor for Operations

- Government Follow On Ship Military Payload Cost Factor

- Maintenance Cost Factors

- Maintenance Cost Factor 1

- Maintenance Cost Factor 2

- Maintenance Hours Cost Factor

- Average Ship Cost Factor for Maintenance

- Fuel Cost Factors

- Fuel Cost

- Fuel Conversion Factor

- Major Support Factors

- Major Support Factor 1

- Major Support Factor 2

- Major Support Operating Hours Cost Factor

- Other Factors

- Average Ship Cost Factor

- Residual Value Cost Factor

Total Crew represents the total number of crew onboard, including both ship's force personnel and those that support the airwing.

Ship Service Life is the intended total service life of the ship in years, from its commissioning to its retirement.

Production Rate is the intended number of ships to be constructed per year. Total Number of Ships in Class is the total number of ships intended to be built and is used to calculate the total Life Cycle Costs of the entire class of vessels.

Year 1st of Class in Service is the calendar year that the 1st ship is intended to be commissioned and differs from the Base Year by the number of years needed to design and build the ship.

Learning Rate Factor (or RL) represents the learning curve assumed in the construction of multiple ships of the same class and a value of 0.97 is suggested as a default. In the method being used the construction costs of follow on ships construction costs for SWBS Groups 100 through 700 and 900 are a fuction of lead ship costs times a factor F which accounts for production learning.

For the first follow ship, this factor, F, is defined by the following equation;

F = 2.0 * (RL) - 1.0

Additionally, the Acquisition Costs of the First Follow On Ship divided by F gets used in the calculations to represent an Adjusted Lead Ship Cost that captures the Recurring Production costs but not any Non-Recurring items.

Research and Development Cost Factors are factors used to account for the R&D entailed in the Design and Construction of a new vessel, and the following default values are suggested;

| Ship Design & Development Factor | 0.1000 |

| Basic Ship Construction Design & Development Factor | 0.5710 |

| Government Military Payload Design & Development Factor | 0.0956 |

| Ship Test and Eval Factor | 0.2000 |

| Basic Ship Constr Test and Eval Factor | 0.4990 |

| Govt Mil Pyld Test and Eval Factor | 0.6470 |

| Payload Hardware Test and Eval Factor | 0.6460 |

Similar to the R&D Cost Factors above, The Basic Ship Construction Test & Evaluation Factor and the Government Military Payload Test & Evaluation Factor represent the T&E costs for those items in terms of a fraction of the Adjusted Lead Ship Cost and the Lead ship Payload Costs respectively, while the ship design and Development Factor is an addition percentage margin on top of this. The Payload Hardware Test & Evaluation Factor represents the cost of T&E for the Government Furnished Equipment (GFE) in terms of Dollars per ton and as such should be escalated from FY 1981 to the Base Year of the vessel. In general, it is recommended that these items be left as their default values.

Shore Based Support & Repair Factors are factors used to account for the costs associated with Shore Based Spares and other such Support and Repair costs for a vessel, and the following default values are suggested;

| Ship Support Equip Factor | 0.0500 |

| Payload Support Equip Factor | 0.2000 |

| Ship Spares and Repair Parts Factor | 0.0300 |

| Payload Spares and Repair Parts Factor | 0.1300 |

( Adjusted Lead Ship Cost ) * ( Total Number of Ships in Class ) ^ ( ln (2 * RL) / ln ( 2 ) )

Similarly the Payload Support Equipment Factor represents the Shore Based Payload Support Equipment Costs as a fraction of the ship's Payload Prime Equipment Costs, where the Payload Prime Equipment Cost is assumed equal to and the Ordnance and Electonics GFE for the Lead Ship and any Follow On ships. In general, it is recommended that these items be left as their default values. The Ship Spares & Repair Parts Factor represents the Shore Supply Spares and Repair parts also in terms of the ship's Prime Equipment Costs, while the Payload Spares and Repair Parts Factor similarly does so based on the Payload Prime Equipment Costs.

Personnel (Pay & Allowance) Cost Factors are factors used to account for the crewing costs of the vessel, and the following default values are suggested (which are based on FY1981 data, which later gets escalated to the Base Year, using the escalation factors discussed on the main Cost page);

| Officer Cost Factor | 0.0262 |

| CPO and Enlisted Cost Factor | 0.0115 |

| TAD Factor | 2.60E-06 |

Here the Officer Cost Factor represents the annual pay & allowance costs associated with each officer onboard the ship while the CPO and Enlisted Cost Factor similarly represents those values for the CPOs and enlisted personnel onboard. The TAD Factor represents an assessement of the TAD costs for a vessel over its service life.

Operations Cost Factors are factors used to account for the operations costs of the vessel, and the following default values are suggested (which are based on FY1981 data, which later gets escalated to the Base Year, using the escalation factors discussed on the main Cost page);

| Operations Cost Factor 1 | 188 |

| Operations Cost Factor 2 | 2.2320 |

| Operating Hours Cost Factor | 0.0372 |

| Avg Ship Cost Factor for Ops | 0.0013 |

| Govt Follow Ship Mil Pyld Cost Factor | 0.0051 |

Operations Cost Fator 1 and 2, the Operating Hours Cost Factor and the Average Ship Cost Factor for Operations are not well defined in any of the sources theses, but appear to likely be empirically derived factors for the operating costs of naval vessels, and probably best left as their suggested default values. The Government Follow Ship Military Payload Cost Factor is a representation of the Annual Cost of Training Ordnance as a fraction of the Follow Ship Ordnance and Electronics GFE.

Maintenance Cost Factors are factors used to account for the maintenance costs of the vessel, and the following default values are suggested (which are based on FY1981 data, which later gets escalated to the Base Year, using the escalation factors discussed on the main Cost page);

| Maintenance Cost Factor 1 | 2967 |

| Maintenance Cost Factor 2 | 4.8140 |

| Maintenance Hours Cost Factor | 0.3279 |

| Avg Ship Cost Factor For Maint | 0.0064 |

Similar to the Operations Factors above the Maintenance Cost Factor 1 and 2, the Maintenance Hours Cost Factor and the Average Ship Cost Factor for Maintenance do not appear to be well defined in any of the sources theses, but likely are empirically derived factors for the maintenance costs of naval vessels, and probably best left as their suggested default values.

Fuel Cost Factors are factors used to account for the fuel costs of the vessel, and the following default values are suggested (which are based on FY1981 data, which later gets escalated to the Base Year, using the escalation factors discussed on the main Cost page);

| Fuel Cost | 0.95 | $/gal |

| Fuel Conversion | 6.8 | lb/gal |

The Fuel Cost listed (I believe) is a default value for Diesel Fuel Marine (DFM) suggested in the references theses for the Fiscal Year 1981, and it is escalated in the spreadsheet to the Base Year using the escalation factors discussed on the main Costs page. If the user wishes to use an alternate value here, he or she should escalate or de-escalate the desired value into FY1981 dollars using the escalation factors discussed on the main Costs page so that it caries through the rest of the calculations correctly. The Fuel conversion rate is for normal DFM and the user can alter this value if other fuel types are used.

Support Cost Factors are factors used to account for the fuel costs of the vessel, and the following default values are suggested (which are based on FY1981 data, which later gets escalated to the Base Year, using the escalation factors discussed on the main Cost page);

| Major Support Factor 1 | 698 |

| Major Support Factor 2 | 5.9880 |

| Major Supt Op Hours Cost Factor | 10.3600 |

Similar to the Operations Factors above the Major Support Factor 1 and 2, and the Major Support Operating Hours Cost Factor do not appear to be well defined in any of the sources theses, but likely are empirically derived factors for the maintenance costs of naval vessels, and probably best left as their suggested default values.

Other Factors include the residual value of the ship and/or costs associated with its disposal at the end of its service life, and the following default values are suggested (which are based on FY1981 data, which later gets escalated to the Base Year, using the escalation factors discussed on the main Cost page);

| Average Ship Cost Factor | 0.0022 |

| Residual Value Cost Factor | 0.5 |

The Average Ship Cost Factor is used in the Costs of Major Support Calcs, and otherwise does not appear to be well defined in any of the reference theses. As such, it is possible that this value is likely an empirically derived input for these calculations and it is recommended that it liekly best be left as its suggested default value.

The Residual Value Cost Factor represents the residual value of the vessel at the end of its service life per the following equation;

Residual Value = Residual Value Cost Factor * Ship Prime Equipment Cost * ( 1 - ( 2 / Service Life )) ^ Service Life

A negative value can be entered here to reflect a disposal cost in lieu of an assumed residual value.

A negative value can be entered here to reflect a disposal cost in lieu of an assumed residual value.

| Life Cycle Cost Element | Equation | |

|---|---|---|

| Ship Design and Development Cost | = | (1 + Ship Design & Dev Factor) * (Basic Ship Constr Des & Dev Factor * Adjusted Lead Ship Cost + Govt Mil Pyld Des & Dev Factor * Lead Ship Ordnance & Electronics GFE) |

| Ship Test and Evaluation Cost | = | (1 + Ship Test and Eval Factor) * (Basic Ship Constr Test & Eval Factor * Adjusted Lead Ship Cost + Govt Mil Pyld Test & Eval Factor * Lead Ship Ordnance and Electronics GFE) |

| Payload Test and Evaluation Cost | = | Payload Hardware Test & Eval Factor * GFE Wt |

| Total Ship Research and Development Cost | = Ship Design & Development Cost + Ship Test & Evaluation Cost + Payload Test & Evaluation Cost | |

|

|

|

|

| Average Ship Cost | = | (Ship Prime Equip Cost + Payload Prime Equip Cost) / Total # of Ships |

|

|

|

|

| Ship Prime Equip Cost | = | Adjusted Lead Ship Cost * Total # of Ships ^ (LN( 2 * RL )/LN(2)) |

| Payload Prime Equip Cost | = | Lead Ship Ordnance & Electronics GFE + (Total # of Ships - 1) * Follow Ship Ordnance & Electronics GFE |

| Ship Support Equipment Cost (Shore Based) | = | Ship Support Equip Factor * Ship Prime Equip Cost |

| Payload Support Equipment Cost (Shore Based) | = | Lead Ship Ordnance & Electronics GFE + (Total # of Ships - 1) * Follow Ship Ordnance & Electronics GFE |

| Ship Spares and Repair Parts Cost (Shore Supply) | = | Ship Spares & Repair Parts Factor * Ship Prime Equip Cost |

| Payload Spares and Repair Parts Cost (Shore Supply) | = | Payload Spares & Repair Parts Factor * Payload Prime Equip Cost |

| Total Investment Cost | = | Ship Prime Equip Cost + Payload Prime Equip Cost + Ship Support Equipment Cost (Shore Based) + Payload Support Equipment Cost (Shore Based) + Ship Spares & Repair Parts Cost (Shore Supply) |

|

|

|

|

| Cost of Pay and Allowances | = | Officer Cost Factor * Officers + CPO & Enlisted Cost Factor * (CPOs + Crew)) * Total # of Ships * Service Life |

| Cost of TAD | = | (Officers + CPOs + Crew) * Total # of Ships * Service Life * TAD Factor |

| Total Cost of Personnel (Pay & Alllowances) | = | Cost of Pay & Allowances + Cost of TAD |

|

|

|

|

| Cost of Operations | = | Total # of Ships * Service Life * (0.001 * (Operations Cost Factor 1 + Operations Cost Factor 2 * (Officers + CPOs + Enlisted) - Operating Hours/Year * Operating Hours Cost Factor) + Average Ship Cost * Avg Ship Cost Factor for Ops + Ordnance and Electronics GFE (Follow) * Govt Follow Ship Mil Pyld Cost Factor) |

| Total Maintenance Cost | = | Total # of Ships * Service Life * (0.001 * (Maintenance Cost Factor 1 + Maintenance Cost Factor 2 * (Officers + CPOs + Enlisted) - Operating Hours/Year * Maintenance Hours Cost Factor) + Average Ship Cost * Avg Ship Cost Factor For Maint) |

| Total Fuel Cost | = | Total # of Ships * Service Life * Fuel Cost * (Operating Hours/Year) / Fuel Conversion * Approx Fuel Rate * 2240 / 1000 / 1000 |

| Replenishment Spares Cost | = | (Ship Spares and Repair Parts Cost (Shore Supply)Ship Spares and Repair Parts Cost (Shore Supply) + Payload Spares and Repair Parts Cost (Shore Supply) ) * (Service Life - 4) / 4 |

| Cost of Major Support | = | Total # of Ships * Service Life * (Major Support Factor 1 +Major Support Factor 2 * (Officers + CPOs + Enlisted) - (Operating Hours/Year) / Major Supt Op Hours Cost Factor) / 1000 + Average Ship Cost Factor * Average Ship Cost |

| Total Operating and Support Cost | = | Total Cost of Personnel (Pay & Alllowances) + Cost of Operations + Total Maintenance Cost + Total Fuel Cost + Replenishment Spares Cost + Cost of Major Support |

|

|

|

|

| Residual Value | = | Residual Value Cost Factor * Ship Prime Equip Cost * ( 1 - 2 / (Service Life)) ^ 'Service Life |

|

|

|

|

| Total Life Cycle Cost (Undiscounted) | = | Total Ship Research and Development Cost + Total Investment Cost + Total Operating and Support Cost - Residual Value |

This document maintained by PFJN@mnvdet.com.