Margins & Allowances Estimation

Weight & VCG MarginsTypically in ship design, a certain amount of margins are included into the light ship weight and VCG estimates to account for;

- uncertainties in the calculations and weights used to estimate the vessel's lightship weight,

- potential design changes that will occur during construction,

- weight growth during detailed design and construction that can occur as more detailed design is performed and better estimates & calculations are undertaken,

- potential revisions to the contract during design and construction, and

- possible additional equipment etc that the government may want to add to the vessel during design and construction, etc.

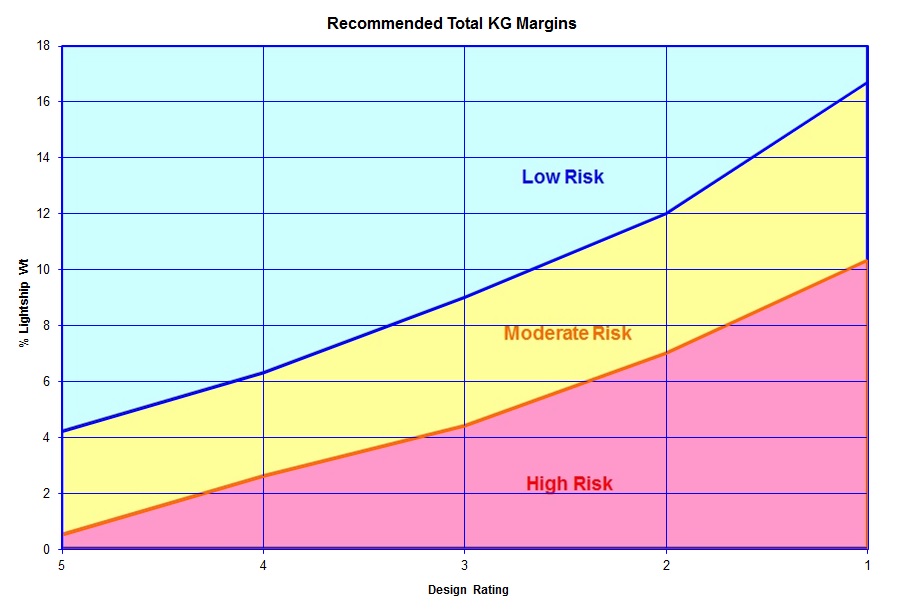

Not too long ago the US Navy put together a document providing guidelines for how much margin would be appropriate for early stage designs based on how risky the design is and how much effort the ship builder is willing to put into mitigating weight growth during construction. This document is called NAVSEAINST 9096.6B "Policy for Weight and Vertical Center of Gravity Above Bottom of Keel (KG) Margin for Surface Ships". As I understand it, much of this information is also reproduced in "Recommended Practice Number 14" from the Society of Allied Weight Engineers, entitled "Weight Estimating and Margin Manual for Marine Vehicles".

In these documents the USN categorizes ship designs into five different categories by how much risk is inherent in the design. These categories include:

- Developmental designs with a high level of uncertainty

- New concept design with some significant level of uncertainty

- Designs similar to existing designs but with major changes and an associated level of some uncertainty

- Designs similar to existing designs with minor changes and only a small level of uncertainty,

- Follow-on designs with only minor changes and almost no uncertainty

- if you were trying to recreate an existing design, I would define it as a Category 5 vessel,

- if you were trying to investigate a relatively simple modification to an existing design, such as investigating fitting an alternate existing weapons, sensor, or propulsion engine, etc or if you were trying to investigate a design that, while not being directly derived from an existing design, it is still very conventional, and uses existing weapons, sensors, and propulsion engines, etc I would also define these as Category 4 vessels,

- if you were trying to investigate a more complex modification to an existing design, such as investigating fitting a limited number of alternate not currently existing/developmental gun sensor, or propulsion engine, etc or if you were considering fitting a completely new propulsion plant, or if you were trying to investigate a design that, while not being directly derived from an existing design, it is still very conventional, but uses a limited number of not currently existing/developmental weapon, sensor, or propulsion engine, etc I would also define these as Category 3 vessels,

- If you were trying to investigate any other form of conventional displacement monohull that includes a significant number of not currently existing/developmental gun sensor, or propulsion engine, etc or some form of radical/new propulsion plant, then I would define these as Category 2 vessels, and finally

- If you were trying to do something else, like a multihull or an all aluminum or composite hull larger than any previously built vessel etc, for now I'd guess that would probably best be described as a Category 1 vessel.

- Recreating vessels like the FFG7, DD963, DDG51, & CG47 etc would all be Category 5 type designs

- Recreating the FFG7 but substituting a 57mm or 127mm gun for the 76mm gun, or a VLS for the Mk13 launcher would be a Category 4 type design. Similarly, investigating a totally new conventional monohull design, outfitting with an existing gun (like the 127mm Mk45) and existing sensors (like the SPS-48 and SQS-53 sonar), and existing gas turbines (like the LM2500) would also probably best be considered a Category 4 type design.

- Recreating the DDG51 but substituting a weapon that is still under development or which was only ever developed as a prototype etc (like the 203mm MCLWG etc) would probably be a Category 3 design. Similarly, investigating a modified repeat of the DDG51 with an alternate power plant based on the MT30 gas turbines would also probably best be described as a Category 3 design, as would a completely new (but conventional monohull) with only a limited amount of developmental equipment (such as if I were to substitute LM2500+ or MT30 gas turbines into the sample Category 4 vessel noted above)

- Trying to design a relatively conventional monohull (similar to the DDG51) but outfitted with SPY3, the AGS gun, PVLS missile launchers, and an integrated electric drive would probably best be described as a Category 2 type design

- For now, trying to develop a design like the DDX or the trimaran LCS would likely be Category 1 designs (for the monohull LCS I'd guess that you should probably consider it part way between a Category 1 and Category 2 design)

- HIGH Risk - There is a high possibility that the design might not meet safety limits (subdivision, strength, service life allowances), which might result in the need to redesign all or part of the ship during detailed design and construction which could significantly impact the overall cost and building schedule for the vessel. As such, extreme weight control measures would be required.

- MODERATE Risk - For vessels falling in this category it is expected that weights can be controlled during detailed design and construction by use of an effective weight control program that would involve incentives, Not-to-Exceed values, and other risk mitigation measures.

- LOW Risk - Vessels falling into this category are considered relatively safe designs with very little uncertainty where weight growth can be controlled during detailed design and construction by applying standard weight control and reporting procedures.

Designing a vessel with only enough margins such that it would fall into the HIGH Risk category, is probably not a good idea unless their is a very good reason too, and it would probably be very costly as extreme weight control measures would likely mean;

- the potential need to use a lot of lighter weight materials and equipment to keep weights down,

- the need to conduct alot of additional analyses to see where the use of this lighter weight materials and equipment would be suitable in place of more conventional stuff,

- a higher overall material (and potentially labor) cost for the design as the lighter weight materials and equipment would likely be more costly than more conventional stuff, as well as

- the potential impacts to the design and building schedule if it is found necessary to redesign a large amount of the ship to implement lighter weight materials and equipment, etc.

For the purposes of

putting together a design evaluation tool I'd suggest prohibiting the

use of margins that would result in the design falling into the HIGH

Risk category (for now).

With respect to designs that fall into the MODERATE Risk

category, as noted above it is expected that weight growth could be

controlled during detailed design and construction so that providing

enough margins for the vessel to fall within this category, is probably

acceptable, but there is probably some additional costs associated with

it (as it will probably require the use of at least some ligher weight

materials and equipment and/or additional engineering, etc).

If a vessel design has enough margins to fall into the LOW risk

category I'd suspect that there probably shouldn't be any appreciable

additional costs, etc associated with that design.

As such, for the design evaluation tool I would suggest the following:

|

Recommended Wt Margin |

|||

|

Category |

Description |

for Moderate Risk | for Low Risk |

|

1 |

Developmental designs with a high level of uncertainty | 15.5% | 26% |

|

2 |

New concept design with some significant level of uncertainty | 10% | 18% |

|

3 |

Designs similar to existing designs but with major changes and an associated level of some uncertainty | 6% | 12% |

|

4 |

Designs similar to existing designs with minor changes and only a small level of uncertainty | 3% | 8% |

|

5 |

Follow-on designs with only minor changes and almost no uncertainty | 1% | 6% |

|

Recommended VCG Margin |

|||

|

Category |

Description |

for Moderate Risk | for Low Risk |

|

1 |

Developmental designs with a high level of uncertainty | 10.3% | 16.7% |

|

2 |

New concept design with some significant level of uncertainty | 7.0% | 12.0% |

|

3 |

Designs similar to existing designs but with major changes and an associated level of some uncertainty | 4.4% | 9.0% |

|

4 |

Designs similar to existing designs with minor changes and only a small level of uncertainty | 2.6% | 6.3% |

|

5 |

Follow-on designs with only minor changes and almost no uncertainty | 0.5% | 4.2% |

Service Life Weight Allowance

For naval vessels, an allowance is typically made for weight growth after the ship enters service. This is refered to as a ship's Service Life Allowance (or SLA). The SAWE Recommended Practice #14 - "Weight Estimating and Margin Manual for Marine Vehicles" document provides the following recommendations for naval vessels:

| Ship Type: | Weight |

VCG |

Anticipated Service Life |

|

| (%) | (m) | (ft) | (Years) | |

| Combatants | 10.0 | 0.30 | 1.0 | 20 |

| Carriers | 7.5 | 0.76 | 2.5 | 30 |

| Amphibious warfare ship types | ||||

| a. Large deck | 7.5 | 0.76 | 2.5 | 30 |

| b. Other | 5.0 | 0.30 | 1.0 | 20 |

| Auxiliary ship types | 5.0 | 0.15 | 0.5 | 20 |

| Special ships and craft | 5.0 | 0.15 | 0.5 | 20 |

| Notes:

Weight percentage based on the predicted full load departure

displacement at delivery VCG Values based on the predicted full load departure

VCG @ delivery

|

||||

This document states that "SLAs shall be included in all new and modified repeat designs such that, when delivered, each U. S. Navy surface ship shall be capable of accommodating the anticipated growth of weight and KG during its service life without compromise of the hull strength, reserve buoyancy, and stability characteristics established for the class." The document also notes that "an increased SLA may be required for ships with longer projected service lives." As such, for now for surface combatant designs (like corvettes, frigates, destroyers, and cruisers) I would suggest using a value of 0.5% of a design's full load displacement @ departure (ie with full fuel tanks and a complete loadout of stores) as a suitable Service Life Weight Allowance.